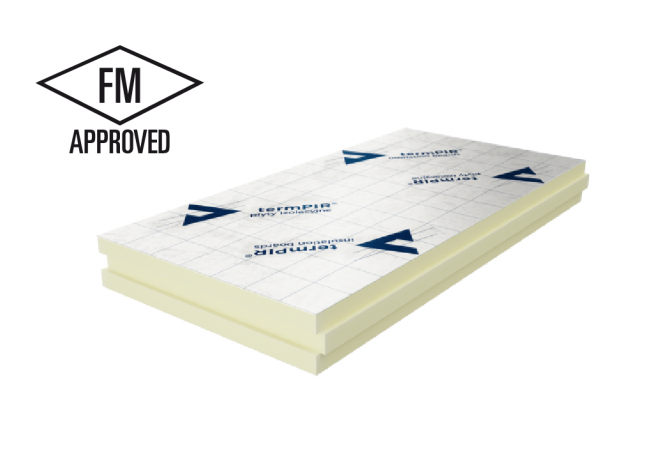

PIR Insulation Board termPIR® Pro-F

Unbeatable solution for increasing energy efficiency of your building!

The termPIR® Pro-F insulation boards comprise of a PIR rigid foam thermal insulation core. The boards are protected on both sides with a gas tight lining layer composed of aluminium, paper and polyethylene.

-

Technical data

-

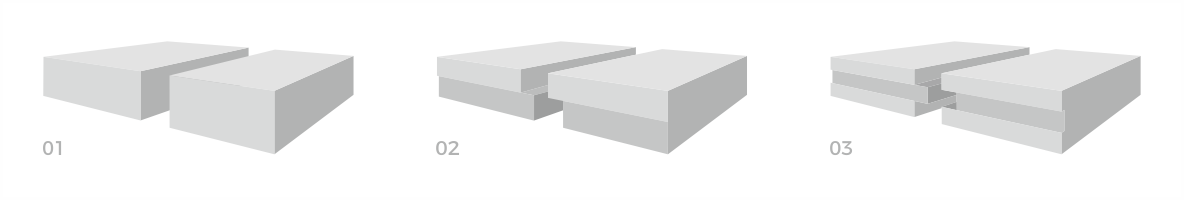

Joint types

-

Logistics: 1200 mm x 600 mm

-

Logistics: 1200 mm x 2400 mm

-

Certificates

Milled edges facilitate assembly and increase thermal insulation.

Joint types:

01. FIT (flat milling from 20-250 mm), 02. LAP (stepwise milling from 40-250 mm)*, 03. TAG (tongue and groove from 40-250 mm)*

* dimensions of boards with joint types are 2 to 4 % smaller

Loading and Unloading is carried out manually by single packages or using a fork lift provided with a grab for some packages. In case of longer, not typical panels, the relevant equipment or more persons should be provided for unnloading. In this way, panel breaking or damage can be prevented.

Note!

Boards are prone to damage, also when they are in the packaging. It is not allowed to throw or roll the packages. The transport of thermal insulation boards should be executed by trucks intended for this purpose. Upon the reception of insulation boards, the number and quality of the delivered commodities should be checked. Discrepancies should be described in the shipping list and reported to the manufacture immediately. Possible damage to boards on the truck should be documented with photographs.

Storage recommendations

- packagesshould be stored in a dry place; they should not be put directly on the ground, but supports should be used,

- do not place heavy objects on the panels, this can cause serious damage,

- protect from weather conditions,

- single boards should be transported vertically so as to avoid their breaking.

termPIR® thermal insulation boards are packed in packages enabling their handling. The typical package height is 500 mm.The number of panels depends on its thickness.

In the table belowe are the basic logistics parameters of termPIR® products. Detailed information has been included in the LOGISTICS CARDS.

Loading and Unloading is carried out manually by single packages or using a fork lift provided with a grab for some packages. In case of longer, not typical panels, the relevant equipment or more persons should be provided for unnloading. In this way, panel breaking or damage can be prevented.

Note!

Boards are prone to damage, also when they are in the packaging. It is not allowed to throw or roll the packages. The transport of thermal insulation boards should be executed by trucks intended for this purpose. Upon the reception of insulation boards, the number and quality of the delivered commodities should be checked. Discrepancies should be described in the shipping list and reported to the manufacture immediately. Possible damage to boards on the truck should be documented with photographs.

Storage recommendations

- packagesshould be stored in a dry place; they should not be put directly on the ground, but supports should be used,

- do not place heavy objects on the panels, this can cause serious damage,

- protect from weather conditions,

- single boards should be transported vertically so as to avoid their breaking.

termPIR® thermal insulation boards are packed in packages enabling their handling. The typical package height is 500 mm.The number of panels depends on its thickness.

In the table belowe are the basic logistics parameters of termPIR® products. Detailed information has been included in the LOGISTICS CARDS.

Why is it worth?

λD = 0,022 W/mk

One of the coefficients on the market.

They do not distort during use. They are light - boards 120 mm thick weight only 3,6/kg/m.

They can be installed almost all year round because they do not absorb water.

You don't have to share the house with rodents and insects, or worry about fungi or mold

They don't keep the fire burning.

You don't need a specialist for assembly