PIR Insulation Board termPIR® AL OSB

Unbeatable solution for increasing energy

efficiency of your building!

termPIR® AL OSB insulation boards consist of a termPIR® board with a PIR foam core covered on both sides with a gas-tight sandwich cladding based on paper, aluminum and an OSB board with a thickness of 8 to 22 mm. There is an adhesive layer between the plate with aluminum cladding and the OSB board.

-

Technical data

-

Joint types

1

Kind of core:

Rigid polyisocyanurate foam(PIR)

2

Density [kg/m3]:

p = 30 kg/m3

3

Declared heat transfer coefficient for lining λ:

λD = 0,022

4

Type of facing:

Both sides with a lining based on paper and aluminum with GK board

5

Standard board dimensions [mm]:

1200 x 2500

6

Joint types*:

FIT - flat milling

7

Board thicknesses available [mm]:

from 20 to 250 mm

8

Board thickness [mm]:

20

30

40

50

60

70

80

90

9

Thermal resistance RD* :

0,90

1,35

1,85

2,30

2,75

3,25

3,70

4,15

10

Heat transfer coefficient U for roof* :

0,96

0,67

0,50

0,41

0,35

0,29

0,26

0,23

11

Heat transfer coefficient U for wall and floor* :

0,93

0,66

0,50

0,40

0,34

0,29

0,26

0,23

12

Board thickness [mm]:

100

110

120

130

140

150

160

-

13

Thermal resistance RD* :

4,65

5,10

5,55

6,05

6,50

6,95

7,45

-

14

Heat transfer coefficient U for roof* :

0,21

0,19

0,18

0,16

0,15

0,14

0,13

-

15

Heat transfer coefficient U for wall and floor* :

0,21

0,19

0,17

0,16

0,15

0,14

0,13

-

16

Reaction to fire (single board):

E class (from the OSB side), F class (from the PIR side)

17

Note:

* thermal resistance R and U coefficient apply only to PIR boards, without additional cladding

Milled edges facilitate assembly and increase thermal insulation.

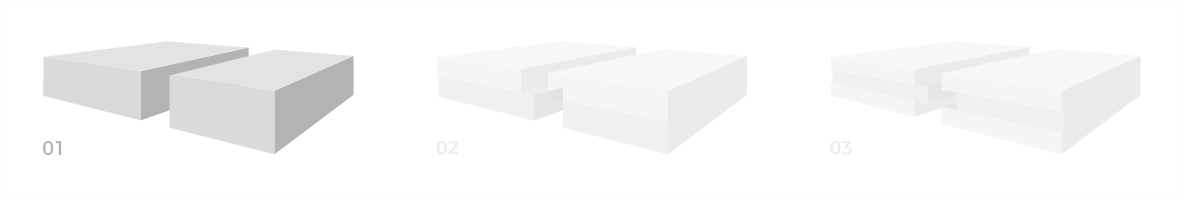

Joint types:

01.FIT (flat milling from 20- 250 mm), 02. LAP (stepwise milling from 40-250 mm)*-lack, 03. TAG (tongue and groove from 40-250 mm)*- lack

* dimensions of boards with joint types are 2 to 4 % smaller