PIR Insulation Board termPIR® AL GK-OSB

Unbeatable solution for increasing energy

efficiency of your building!

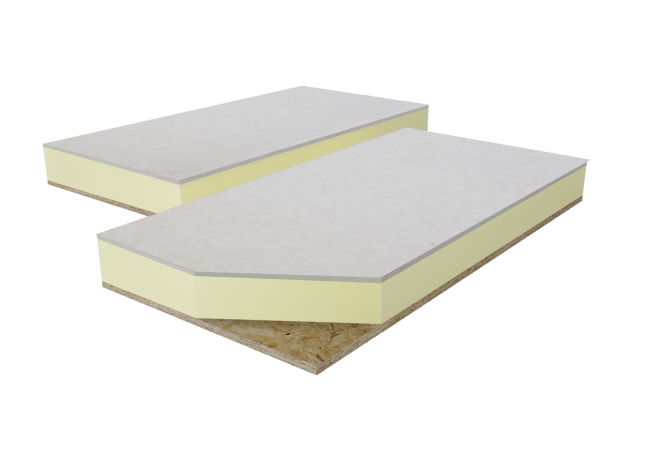

termPIR® AL GK-OSB insulation boards consist of a termPIR® board with a PIR foam core covered on both sides with a gas-tight sandwich lining based on paper, aluminium and an 8 to 22 mm OSB board and a 12.5 mm thick GK board. There is an adhesive layer between the board with a glass veil cladding and the GK/OSB boards.

-

Technical data

-

Joint types

* thermal resistance R and U coefficient apply only to PIR boards, without additional cladding

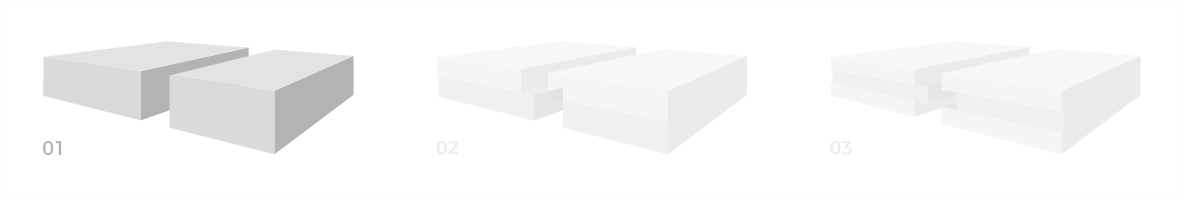

Milled edges facilitate assembly and increase thermal insulation.

Joint types:

01.FIT (flat milling from 20- 250 mm), 02. LAP (stepwise milling from 40-250 mm)*-lack, 03. TAG (tongue and groove from 40-250 mm)*- lack

* dimensions of boards with joint types are 2 to 4 % smaller